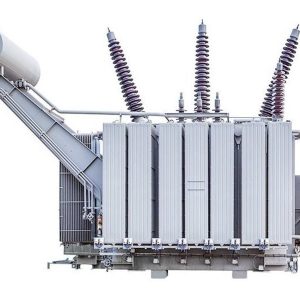

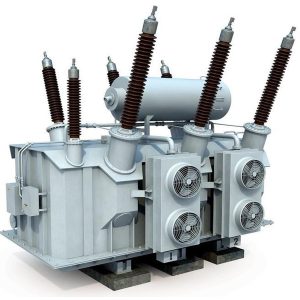

EMC Steel is a global company which provides state-of-the-art engineering and manufacturing for all our transformer products. Including Solar Photovoltaic Inverter Transformers, Power Transformers, Distribution Transformers, Dry Type Transformers, Rectifier Transformers and Electric Arc Furnace Transformers.

We supply the Industrial Power Sector, Metallurgy, Substation, and Solar Energy Industries. Kindly review our products and contact us with any questions or quote requests.